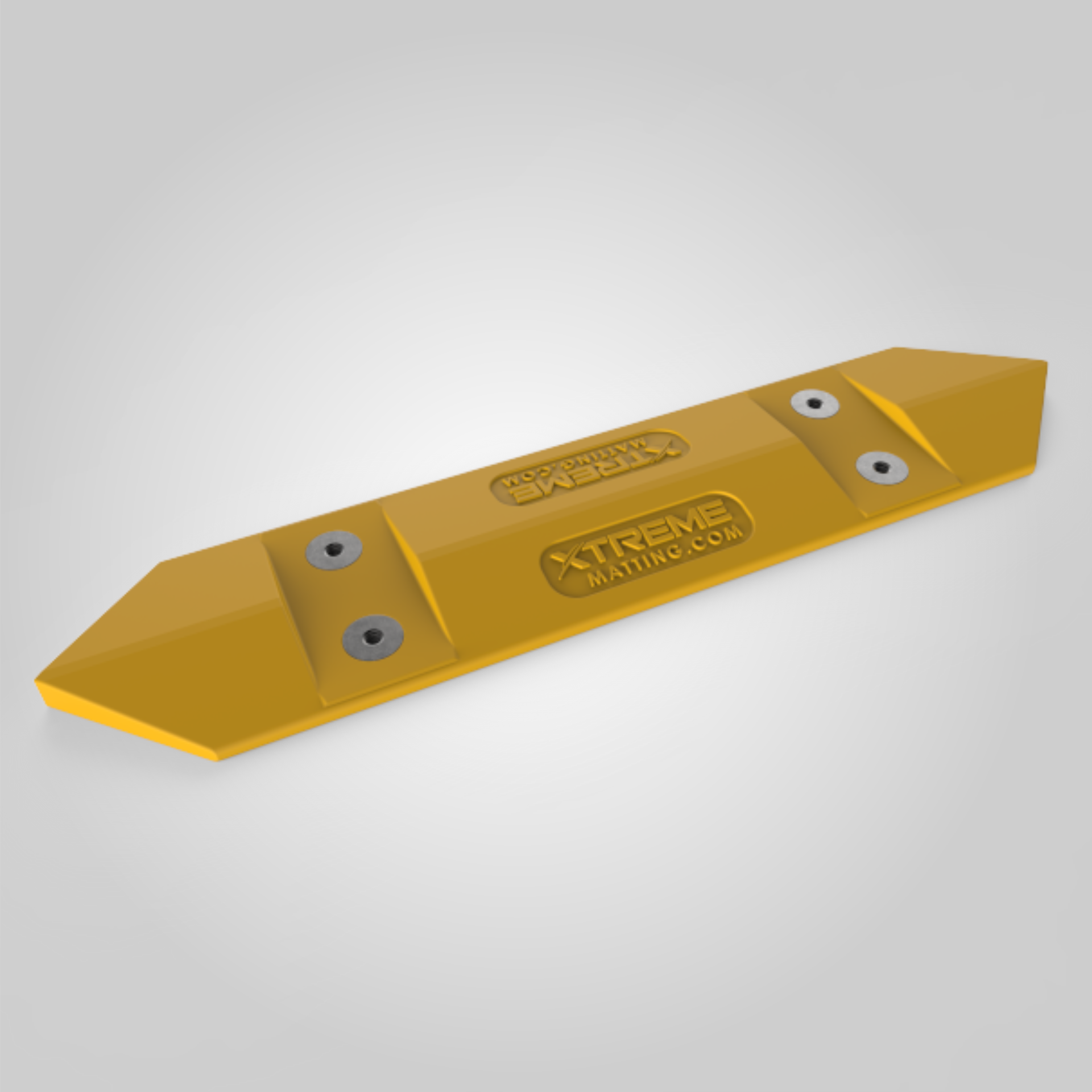

How is the XTREME mat Manufactured?

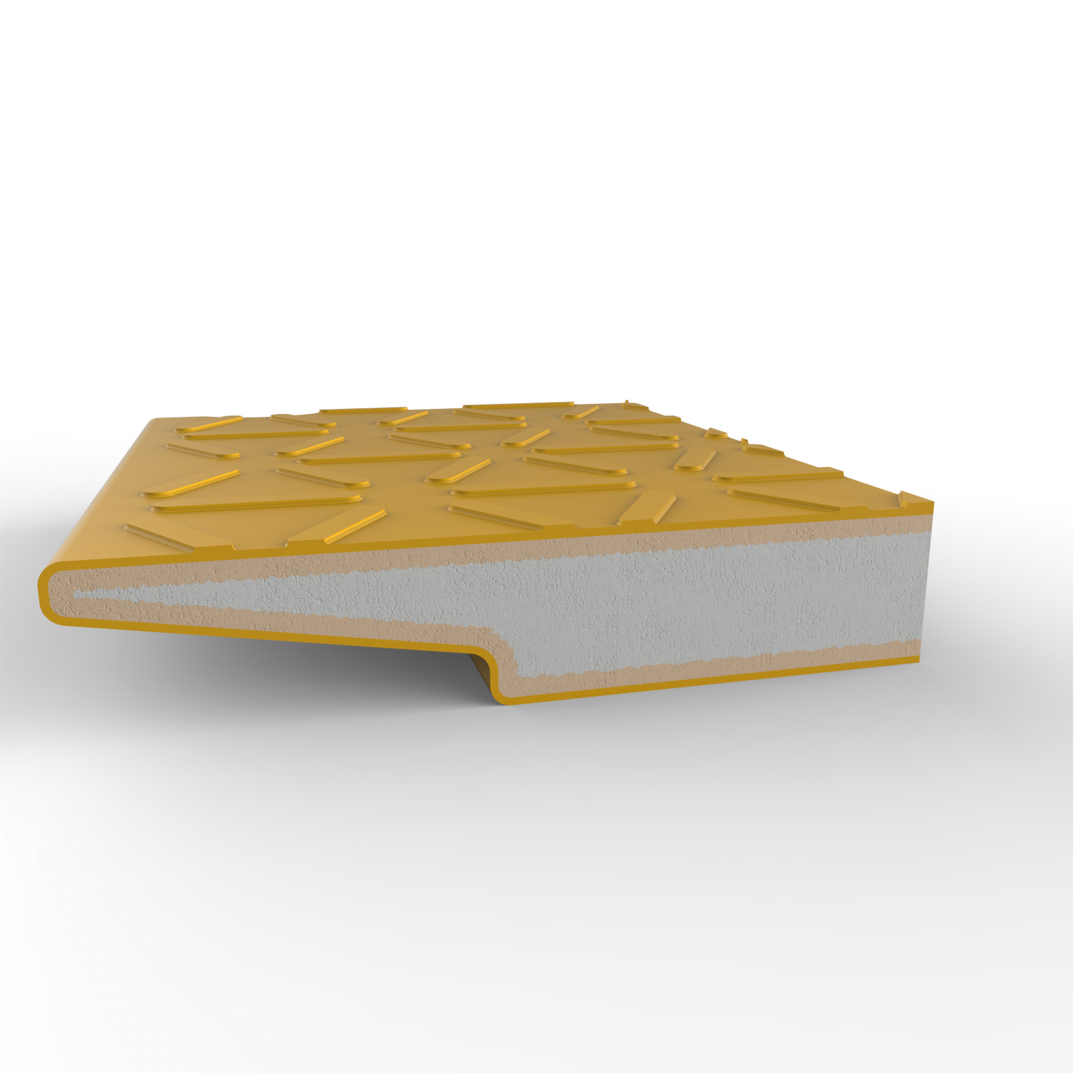

Our XTREME mat is manufactured by a process called rotomolding. We use a proprietary rotomolding technique with some of the largest machines in the Industry. With our unique methods we are able to manufacture large industrial heavy duty HDPE mats with an internal one piece solid plastic core which is why our Xtreme Mat is the strongest HDPE mat manufactured.

What is the difference from the XTREME mat to the competitors?

Our XTREME mats' Solid Core is unique to the industry. The mat is manufactured into a single piece HDPE solid core internal structure which is very unlike our competition that uses a seamed two piece mat with a honeycomb style core. The massive benefits of having single continuous piece core is it make our mat extremely strong in compared to others, plus if the mat surface is breached, there is no space in the core, that can absorb cross-contamination fluids or debris.

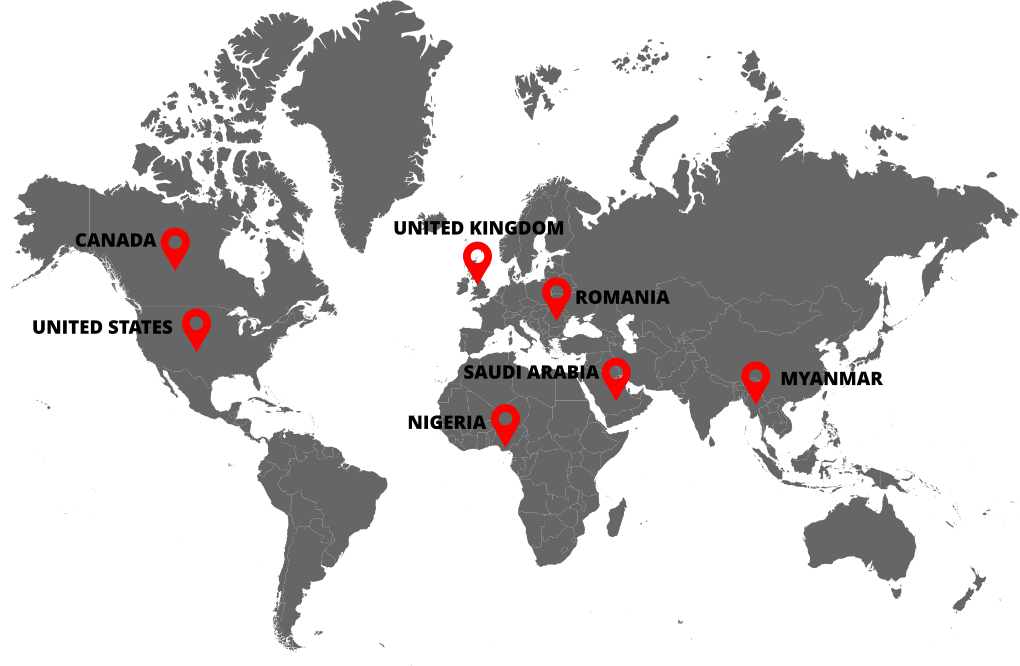

Where is the XTREME mat manufactured and shipped from?

Our XTREME mat is manufactured & shipped from Northeastern Canada from the City of Tracadie-Sheila, New Brunswick. For overseas shipments, the nearest Port from our location is St. John, New Brunswick.

What is the compressional load or the XTREME mat?

The compressional load of the XTREME mat has been rated to 828 PSI / 56 kg/cm2 / 852 Ton/m2. However, we have actually tested the mat with loads nearly 2 times those limits without any signs of mat failure that only showing minimal surface damage. The reason our mat has such a high compressional strength is due the mats' Solid Core design. The internal structure is filled with HDPE closed cell plastic and has no void spaces making the structure completely homogeneous and extremely strong.

Do you have an Sales Representative in our area?

We typically sell directly to the end users, our sales team is located in Western Canada and can be reached by using the contact us form at the bottom of this site.

What is the maximum weight the XTREME mat can handle under extreme temperature conditions?

The XTREME mats are rated to operate within these temperature ranges (-50 °C / -58 °F) to (60 °C / 140°F) with compressional bearing capacities of 56 kg/cm2 / 828 PSI / 582 ton/m2 which is the highest in the industry of comparable matting.

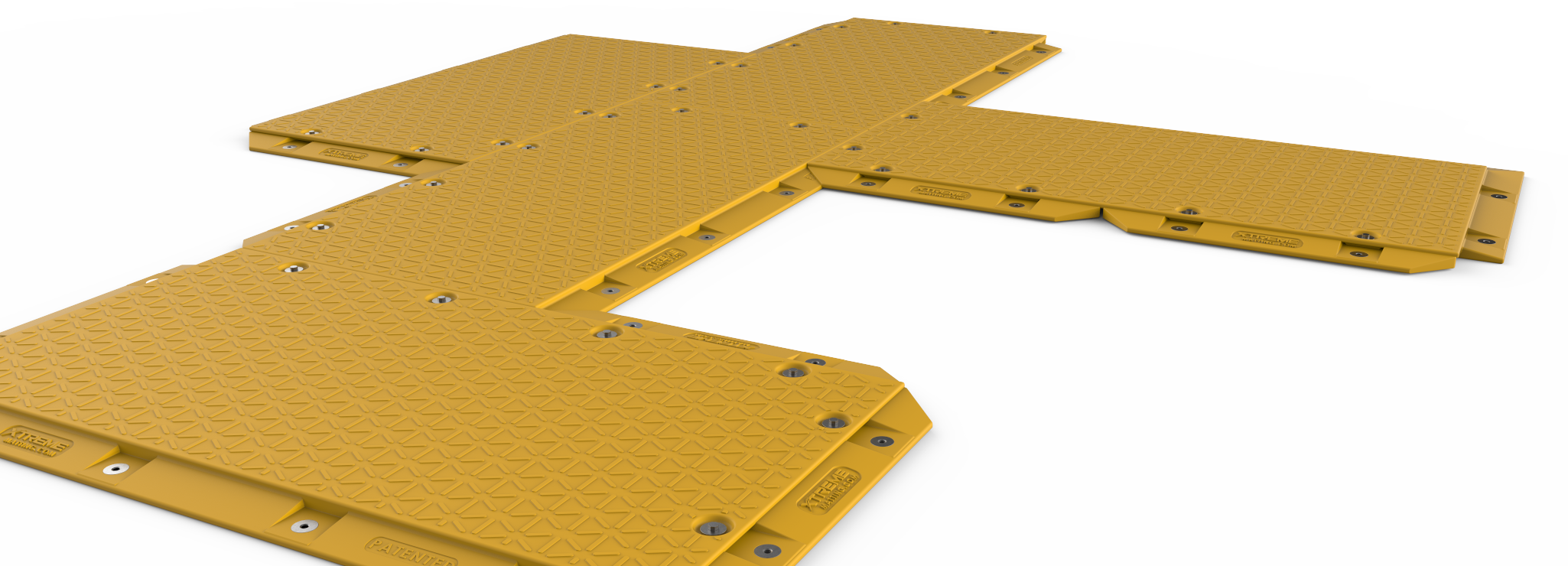

Can the XTREME mat be used on a Drilling Rig site??

Yes, we have clients using our XTREME mats in their rental fleets for many applications. The mats are typically used as working platforms, temporary access roads and or even as a base layer on drilling rig sites. Like most other comparable composite mats on the market, if used as a base layer under a drilling rig, rigid rig mats are still required in conjunction with our Xtreme mat. Typically the rigid rig mats get placed over top of our matting for added stability to meet their engineering requirements. In this type of application our mats bearing load capacity limits normally exceed the engineered minimum weight requirements due to our solid HDPE core design and technology.

Does the XTREME mat fit into standard shipping container?

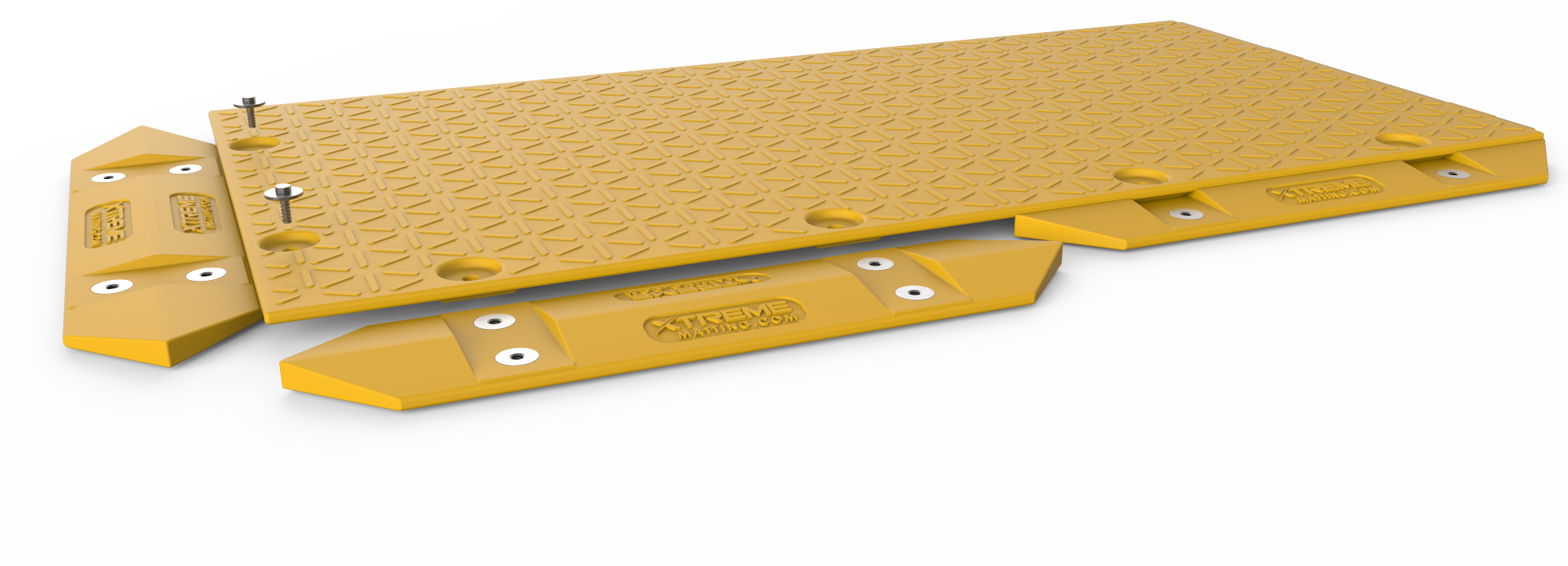

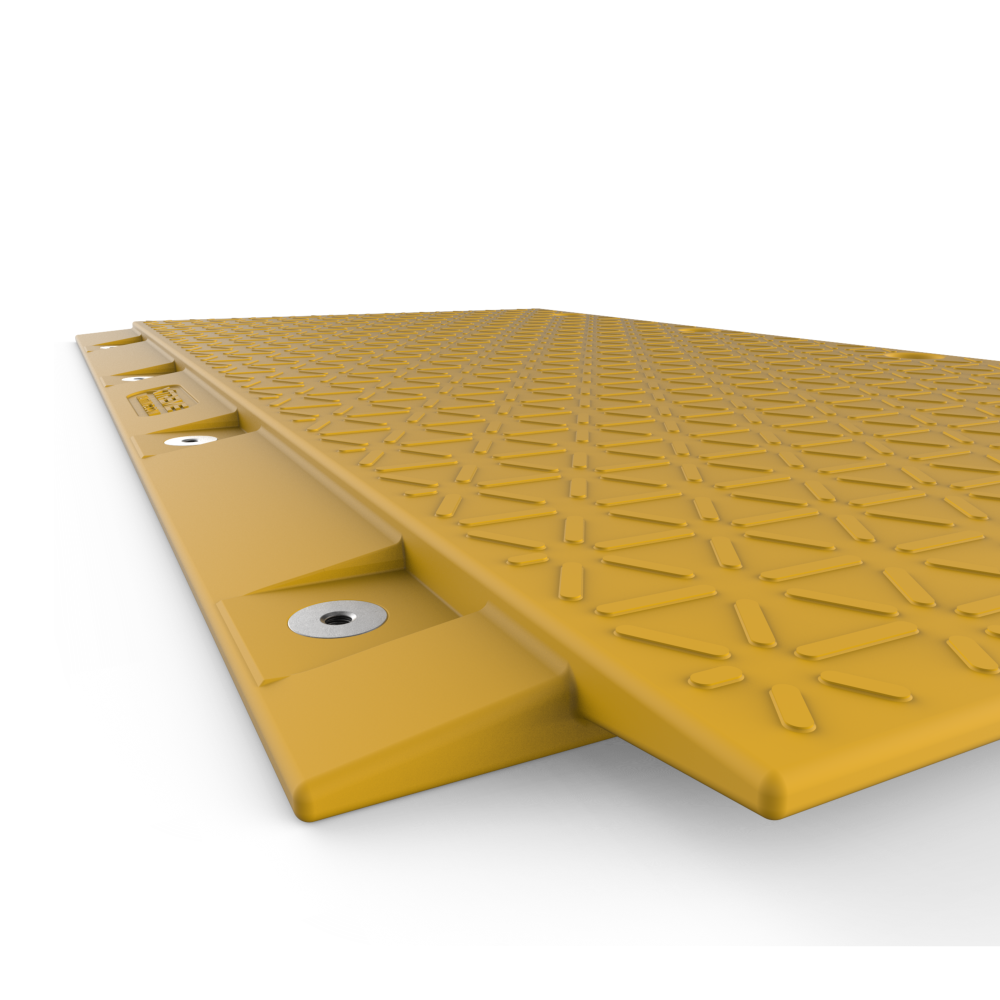

Yes, our XTREME mats are sized to fit safety flat inside a standard shipping container. The mats physical outside dimensions are: Length 4.34m / 14.25ft, Width 2.29m / 7.5ft, Thickness 100mm / 4in. We typically get 40 mats in a standard 40' container or 20 mats in a 20' container.

Can the XTREME mat overlap transition connection provide lateral stability for weights over 20 Tons?

Yes, the weight bearing capacity of the any part of the mat system including the overlap connection and transitional support pieces have a bearing capacity of strength of 56 kg/cm2 / 828 PSI / 582 ton/m2.

Can the XTREME mat be repaired if damaged?

Yes, we offer an optional HDPE welding tool that comes with c/w HDPE spooled material that can seam or patch repair our matting if damaged. This tool requires minimal training and can be used in the field.

Does the XTREME mat use any recycled material and can it be recycled?

Our Xtreme mat is manufactured using 100% virgin HDPE material and can be 99% recycled. Typically on average the valued recovered can range between $300-$500 USD depending on the recycling center rates.